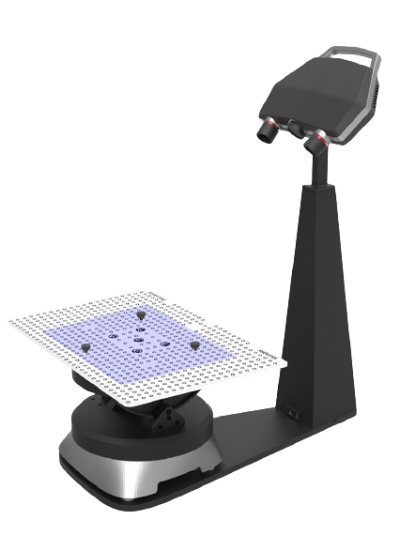

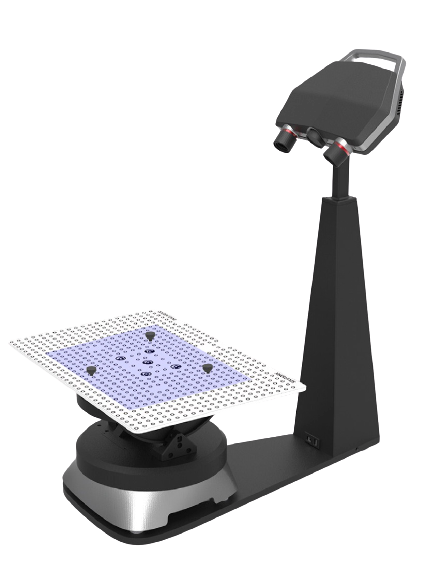

Solutionix C500

Technical Specifications

Scan Modes

Static and Automatic

Light Source

Blue LED

Scan Accuracy

≤ 0.01 mm

Point Spacing

0.028-0.157 mm

Scan Area

30 to 1200 mm

Camera Resolution

2x 0.5 MP

Output Formats

OBJ, STL, ASC, PLY

Scanner Body Weight

2.3 kg

Medit Solutionix C500 Features

Automatic Scanning and Active Synchronization

3D scanning does not always take much work. With a single mouse click, users can get their whole object scanning done very easily and quickly. Another click to actively synchronize the model and camera views, enabling users to recognize any scanning position and to add more scan where it may be needed.

Automatic Calibration

Once the calibration panel is installed, clicking the calibration wizard will guide you through an automated calibration process. The whole calibration process may have been essential, but was difficult for users to follow. Now you will experience a genuinely user-friendly system and a fully automated procedure leading to extreme convenience.

Flexible Scanning Volume

It is equipped with four different types of scan areas from 90mm to 500mm for maximum efficiency and utility in several industrial sectors. For user convenience, the C500 is designed to allow easy changing of the measurement area by simply replacing the projector and camera lens.

Detachable Scanner Head

For scanning of objects that exceed the size or weight limit of the TA300+, the scanner sensor can be easily detached from the C500 stand and then installed on a tripod or other suitable stand for manual scanning.

No Targets or Manual Alignment Needed

Targets are no longer needed for scanning jobs with the Solutionix C500. Using pre-calculated information for axis calibration, accurate alignment is possible without the need for targets or manual registration.

Optimized 3 Axis Automatic Turntable

The C500 industrial 3D scanner is capable of performing scanning tasks easily and rapidly. Solutionix's 3-axis turntable (TA300+) can effectively capture areas beyond the pre-existing limits. The TA300+ is optimized for automatic scanning of small- and medium-sized objects and can hold up to 10kg. With the TA300+, it is possible to work in cramped conditions without much difficulty.

How We Can Help?

As a professional for Reverse Engineering, Mako GmbH recommends the 3D scanners from 3DXpress. We provide up to 2 hours of data processing / reverse engineering for Free!

Installation Help

The Mako GmbH team will help you every step of the way with your new 3D scanner. We will call you and advise you free of charge on installing your 3DXpress scanners.

Service

Mako GmbH converts the scanned point clouds into optimal surfaces. Through the services of us you can process your product geometry without expensive software or employee training and in the highest quality in any CAD system.

Free help

We offer two hours of data processing free of charge for all users who need optimized (surface-recirculated) parametric volume data for CAD systems or high-quality 3D prints after scanning.

Download Brochure

Do you want to learn more about this fascinating device? Click on the button to download the product brochure.