How to Scan an Object for 3D Printing: The Reverse Engineering Workflow

In this article, Reverse Engineering Service expert Mako GmbH explains how Scan an Object for 3D Printing with the help of Reverse Engineering Workflow. There are many steps in this process.

Reverse engineering is important when you want to create new parts that reference or incorporate older designs, where the original CAD design isn’t accessible.

For example, you can create replacement parts that match the original design of damaged existing pieces, or use reverse engineering processes to integrate complex surfaces from existing objects into 3D printable jigs, which are useful when modifying mass manufactured and handcrafted products.

The Reverse Engineering Workflow

To demonstrate the basic steps in a reverse engineering workflow, let's take a look at the process required for creating scan data for 3D printing:

- Prepare the Object for Scanning

Spray coat the object with a temporary matte powder to improve scan accuracy. Even slightly glossy surfaces tend to degrade scan quality, while reflective and transparent surfaces cannot be scanned at all without a matte coating.

- 3D Scan the Object

Use a high accuracy 3D scanner to capture the important sections of the part. Tabletop structure light or laser scanners are the right tools for the job, with accuracy of ±100 or better.

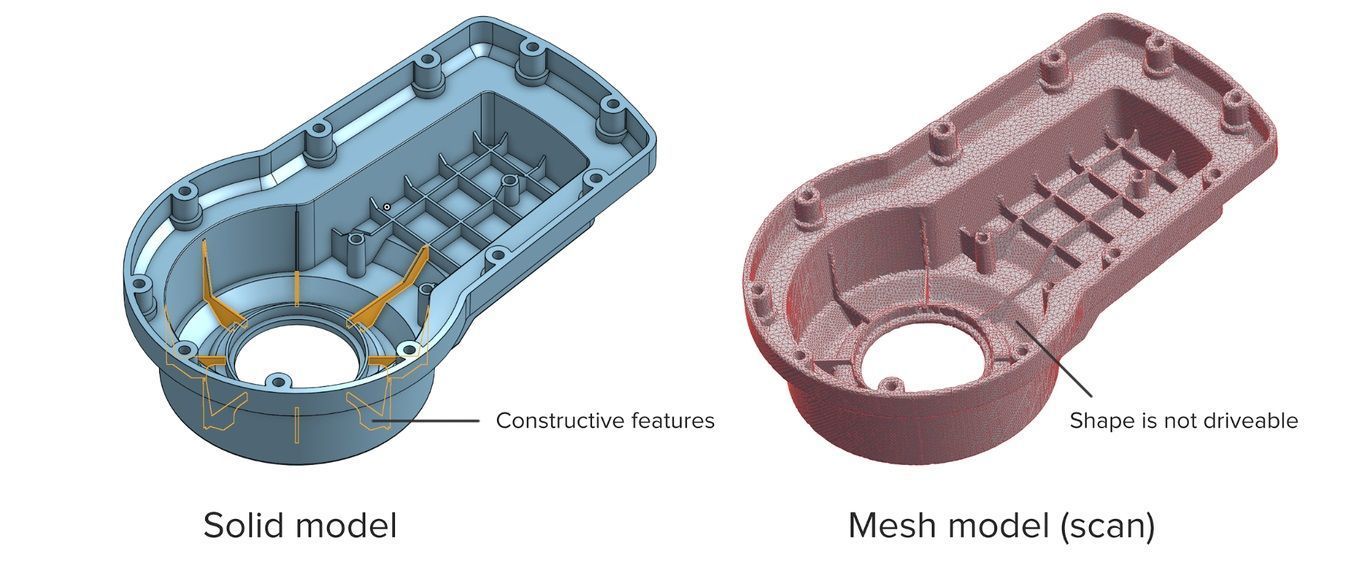

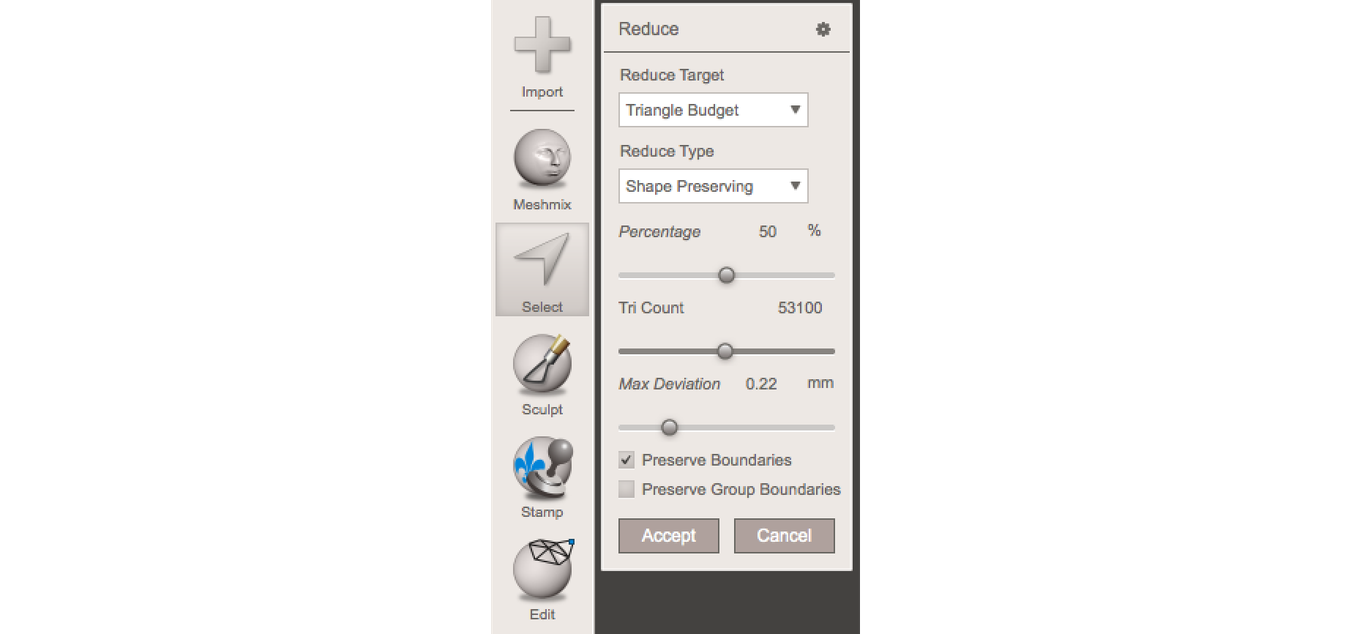

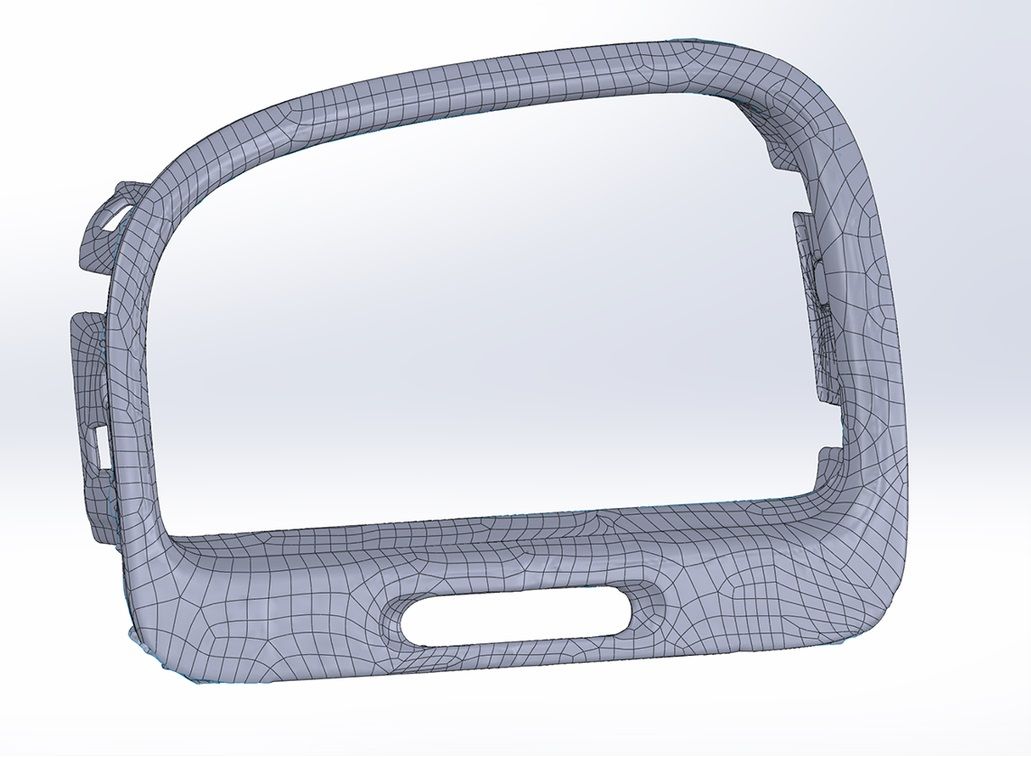

- Refine the Mesh

Some scanners produce extremely large mesh files, which will make later steps grind to a halt.Scanner software repairs small gaps and simplifies the scan, making the data more manageable in CAD. Try to reduce the model as much as possible without destroying important details.

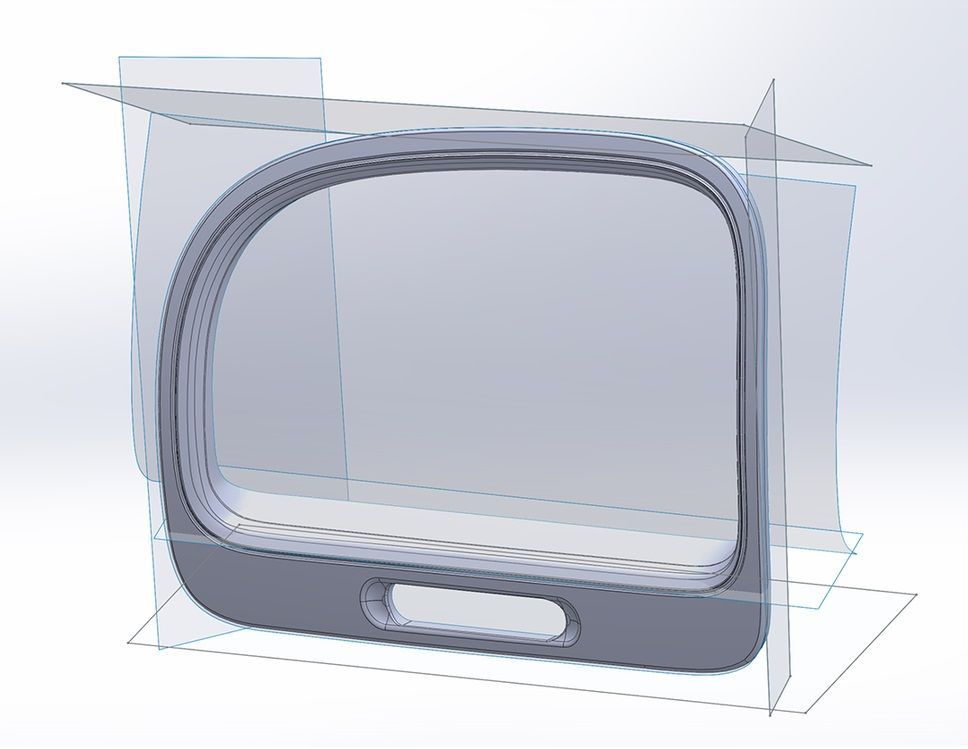

- Import the Mesh to CAD

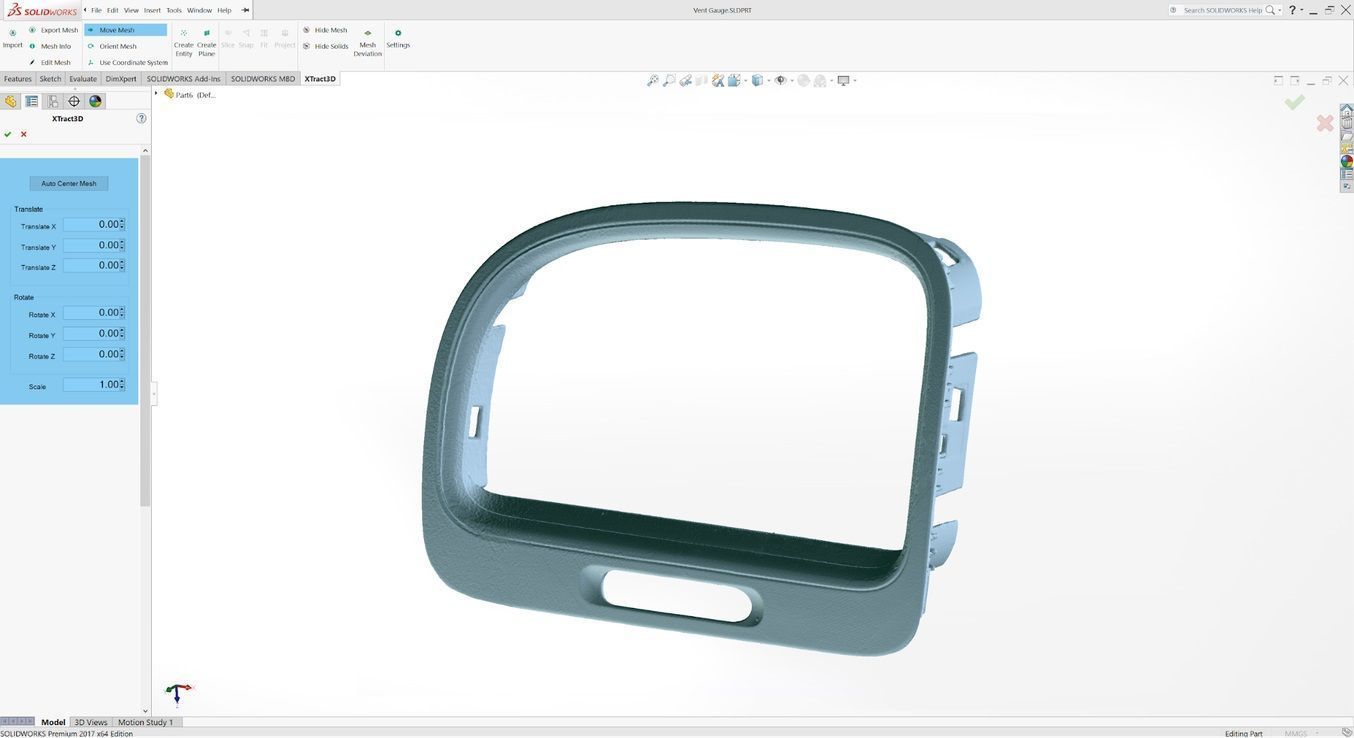

Import the mesh into CAD software equipped with reverse engineering tools. Geomagic for Solidworks is a powerful choice for resurfacing complex, organic shapes.

If you are reverse engineering a part with simpler flat surfaces, Xtract3D is a less expensive, lightweight alternative. In this step, move and rotate the scan mesh into alignment with any existing design components.

- Extract Important Surfaces

There are three paths to extract the shape of the scan in order to create a solid model that is editable with CAD tools: semi-automatic surfacing, automatic surfacing, and manual redrawing.

Semi-automatic surfacing

Complex curved surfaces are difficult to manually draw, so you may choose to use semi-automatic surfacing. This function generates surfaces that fit to detected regions of the scan. By varying the sensitivity of the surface detection function, different surfaces will be found.

Tip: Geomagic for Solidworks detects surfaces on the scan to fit 3D curves. Use a “brush” to manually add or subtract areas on the scan from each region.

You may need to repeat this process several times with different sensitivity settings to detect all your surfaces. These surfaces can then be trimmed and knit together to create an editable solid.

Use semi-automatic surfacing to re-create curved shapes when you want maximum editability later on, and when sharp edge accuracy is important.

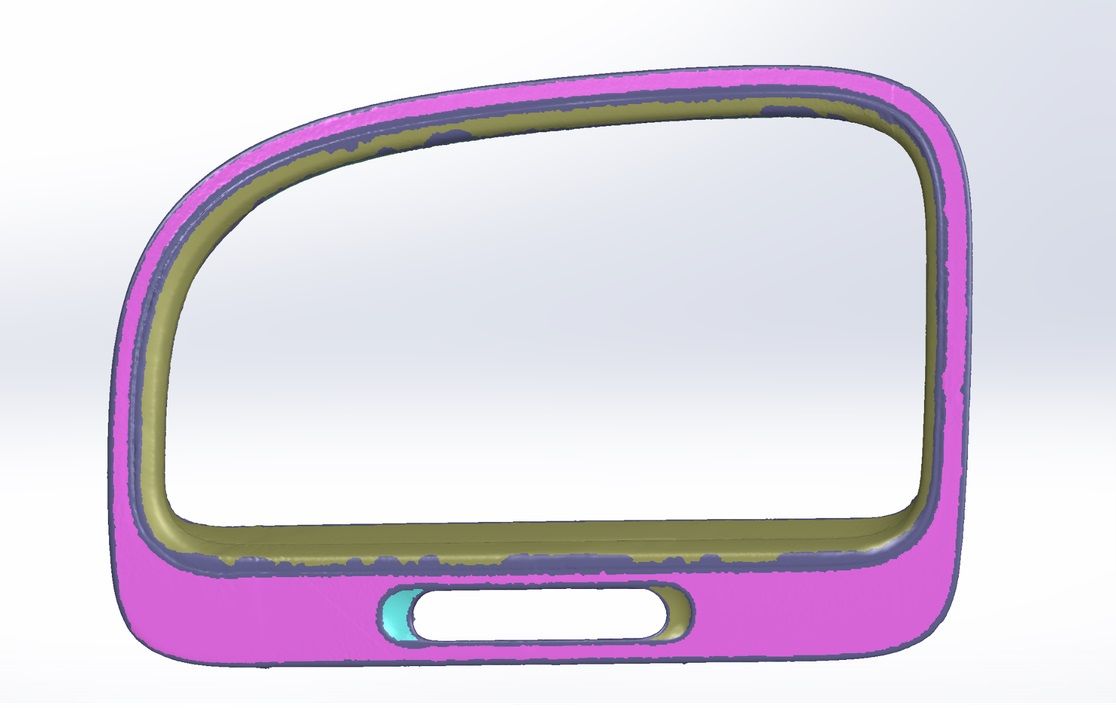

Above is the re-surfaced result, after trimming.

Automatic surfacing

Automatic surfacing generates a solid model from any watertight scan. You can use standard CAD tools to subtract and add to this auto-surfaced body, but it will be more difficult to move basic features around on the body itself.

You may not need control over edge placement. For example, if you are scanning a part of the human body to create custom ergonomically-shaped products, or want to create a jig to precisely or repeatably modify a handmade object. In these cases, automatic surfacing is a great way to save modeling time.

Manual redrawing

For simple features such as bosses, holes, and pockets, it’s usually fastest and most accurate to redraw the features using the scan model as a reference. Reverse engineering software allows you to create sketch planes aligned with flat surfaces on the scan and to extract cross sections from the scan mesh, which helps you match the shape of the original object.

- Integrate New Objects

Once the scan has been converted to a solid, it can be subtracted from another solid body to create a jig that securely holds the original part. The design of the new gauge component also references the dimensions of the scan, using curves extracted with semi-automatic surfacing.

- 3D Print the New Design

Printing the jig on labs (SLA) 3D printer gives you a high degree of accuracy comparable to the output of engineering-grade 3D scanners. Once these steps are complete, the 3D printed jig is ready to use to assemble the new gauge onto the OEM air vent.

The Right Tools for Reverse Engineering

The first step to start reverse engineering parts is to find the 3D scanner that is best suited for your needs. Read about which 3D scanners complement high accuracy 3D printing in our blogs here or visit our website dedicated to 3D scanning and latest 3D scanners here.

If you want to explore more about Reverse Engineering, CAD software and how to master them check out our Blog Posts here or contact us here to get in touch with a Reverse Engineering expert!